The manufacturing of hydraulic filter elements is a precise process combining material science and quality control to remove contaminants from hydraulic fluid under demanding conditions.

1. Material Preparation & Selection #MaterialScience

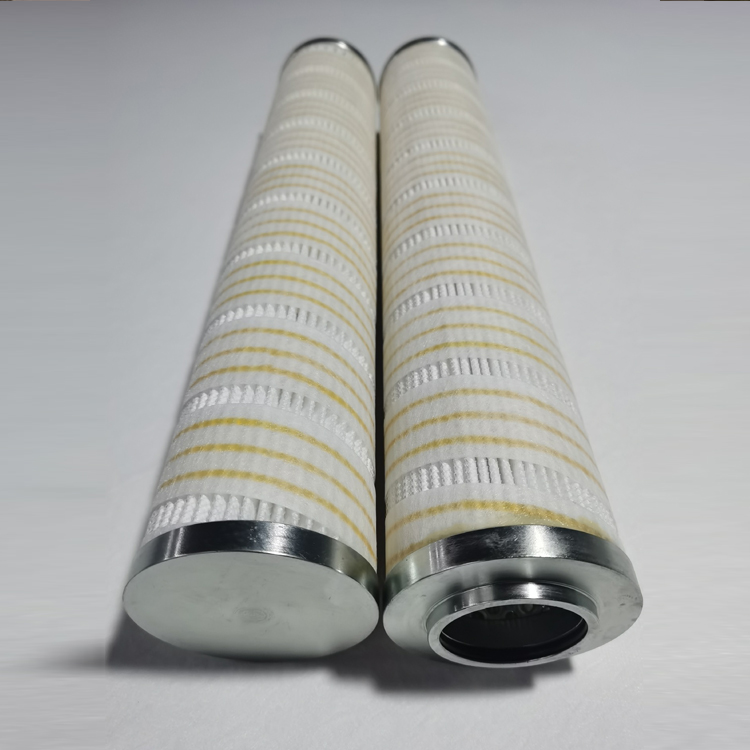

Filter Media: Typically fiberglass (for excellent de-aeration) or metal fiber felt. The choice determines the initial filtration rating (e.g., 1 to 100 microns).

Support Core/Cage: Usually a perforated metal sheet. The thickness (e.g., 0.8mm) is selected based on required pressure resistance.

End Caps: Made from materials like galvanized steel, aluminum, or plastic (if integrated with a bypass valve).

2. Core Manufacturing Process #PrecisionEngineering

Pleating: The filter media is machine-folded into a zig-zag pattern to maximize surface area.

Assembly & Welding: Components (media, core, end caps) are assembled. Welding techniques like plasma welding are critical for metal filters to ensure a strong, leak-proof seal.

Bonding: Epoxy resins are commonly used to securely bond and seal the components together.

3. Rigorous Testing & Validation #QualityControl

Finished filters undergo tests per ISO Standards.

Key tests include: Burst Pressure Resistance, Structural Integrity, Material Compatibility, and Fatigue Resistance.

These ensure reliable performance under high pressure (e.g., 21 MPa/3000 psi) and temperature cycles (e.g., -30°C to +110°C).

Did You Know?

Sintered Metal Filters: For high-strength applications, some filters are made from sintered wire mesh, involving complex welding. They are reusable and cleanable.

Procurement Tip: Understanding the process helps identify quality. Some manufacturers may use thinner support cages (e.g., 0.5mm vs 0.8mm) to cut costs, which can compromise pressure rating and safety.

If you need any inquiry filters,please contact us info@filterreplace.com. We can provide you for one stop service with 12 months warranty time,let you have a good sleep if we are work together.

Contact: Sunny

Phone: 18790023620

Tel: +86 18790023620

Email: info@filterreplace.com

Whatsapp:+86-18790023620

Add: Tiantan Road,Huling Industrial Zones,Jiyuan ,Henan ,China